Two Summerlin: An Office Building with a Unique Exterior Skin

Custom precast panels and energy-efficient elements help set this award-winning project apart.

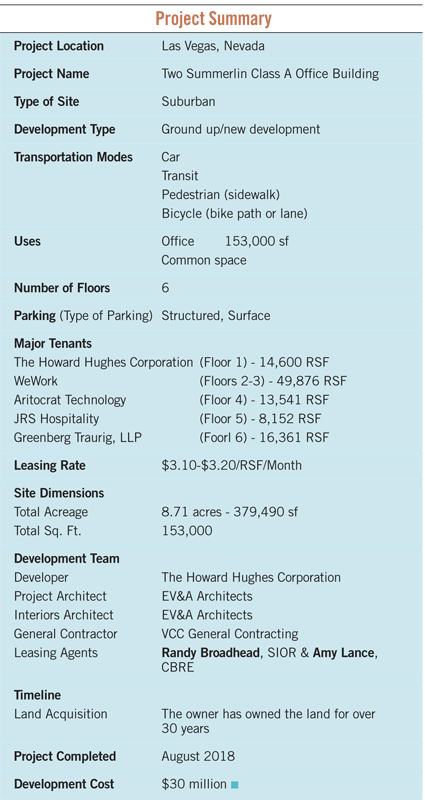

A recently finished six-story, 153,000-square-foot Class A LEED Silver office building in Nevada incorporates a pioneering exterior design process.

Two Summerlin, located in the corporate master-planned community of Downtown Summerlin, serves as the local headquarters of The Howard Hughes Corporation, a national developer of residential, office and retail properties. Downtown Summerlin is one of the company’s developments, and Two Summerlin is the next element of its corporate master plan build-out for the community.

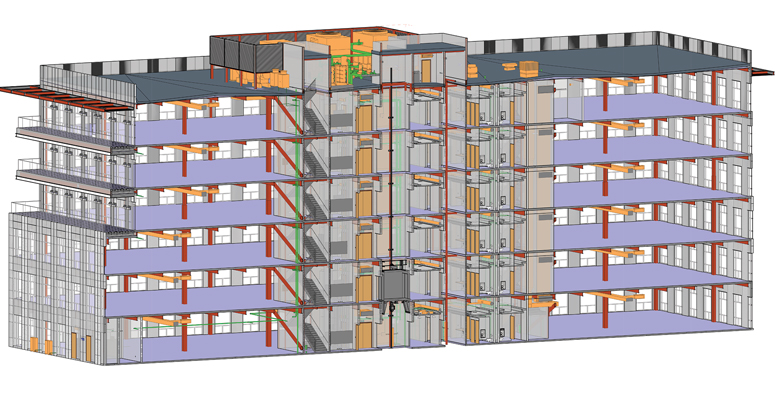

A BIM illustration shows the inside of Two Summerlin, including space for tenants and the location of elevators and other mechanical elements. EV&A Architects

The Howard Hughes Corporation solicited Two Summerlin’s design through a request-for-proposal process and a design competition that attracted national and local architecture firms. The winning design, by Nevada-based Ed Vance & Associates Architects (EV&A), offered high-design yet budget-conscious construction along with knowledge of the area. Matthew Burns, EV&A’s project manager, was responsible for design, construction administration and commissioning.

EV&A Architects, founded in 2006, is the architect of record for hundreds of Howard Hughes Corporation projects. These include the award-winning Aristocrat Technologies headquarters in Las Vegas, the majority of the industrial buildings in the Hughes Airport Center industrial park located near McCarran International Airport in Las Vegas, as well as more than 100 tenant improvement projects for other Howard Hughes Corporation properties.

Precast concrete panels were used for the exterior of Two Summerlin. According to The Howard Hughes Company, it marked the first time this application has been used in Nevada. EV&A Architects

VCC Construction of Irvine, California, was the general contractor and the construction manager of the project, which began in June 2017 and was completed in August 2018.

“There were some challenges for the project including an aggressive schedule and need for early tenant turnover,” said Ron Giebels, vice president of VCC. The project needed to be completed as soon as possible because the owner, The Howard Hughes Corporation, was paying high rent in its existing leased space and wanted to vacate.

Because of that, the VCC team coordinated advanced release of critical trades for the project such as precast, glass and steel to address the client’s goals.

“It takes close collaboration between the architect and contractor for a successful project,” said Giebels. “EV&A has been a partner throughout each phase of this project and has been very helpful in problem-solving. There is a true team atmosphere working with them.”

VCC is a U.S. Green Building Council member and employs numerous LEED Accredited Professionals. It has completed more than 20 LEED projects and built the first green-certified town center in the U.S., Northfield at Stapleton in Denver, Colorado.

A section of the precast concrete panels for Two Summerlin is moved into place at the job site. EV&A Architects

Two Summerlin offers much-needed corporate office inventory for the Las Vegas Valley and was 80 percent preleased prior to its opening in August 2018. Building amenities include state-of-the-art technology such as a water-cooled, variable-volume self-contained mechanical system that produces high-efficiency cooling and heating, LED lighting and high-speed wireless technology. Fourth- through sixth-floor balconies provide views of the Las Vegas Strip and the Red Rock Canyon mountains.

The Design Process

According to EV&A project designer Kevin Welch, the design approach considered many factors, including the building’s orientation relative to the harsh desert sun, to reduce cooling costs and increase tenant comfort. An early concept had a precast concrete exterior screen that hung from the slab edges with floor-to-ceiling glass set back behind it. While this approach was well-received by the client, it was not within the budget. However, it did inspire the idea of utilizing a precast concrete exterior skin.

The precast concrete panels at Two Summerlin are attached to a steel frame structure. Inserts in the panels and rods in the inserts tie the concrete together. EV&A Architects

The design progressed using a formliner product to mold the surface of the precast skin, which produced variations of texture, color and sheen in the exterior finish while staying within the aesthetic of the first proposed concept. The facade breaks up the mass of the overall form through a series of intersecting boxes. They fit in with the surrounding buildings, including the Downtown Summerlin Shopping Center, the City National Arena and One Summerlin office building. That was important, because the town of Summerlin has design requirements and a rigorous design-review process.

The structural design with the custom-molded formliner precast panel system was cost-effective without decreasing the design aesthetic. In fact, the custom aspect of the panels became one of the building’s most notable exterior design features and represents the first time this application has been used in Nevada.

“The design team found a cost-effective approach that offered a nice-looking building for the client,” said Steve Schiller, president of John A. Martin of Nevada, which provided structural engineering services for the project.

The executive office balconies at Two Summerlin, located on the fourth through sixth floors, offer views of the Las Vegas Strip and the Red Rock Canyon mountains. Photographer Michael Tessler

EV&A selected US Formliner to provide custom designs for the 223 panels of various sizes that were used in the project. Ronda Gilbert, Western Regional sales manager for US Formliner, noted that the company sent out a partial shipment of molds to accommodate the accelerated construction schedule. The first shipment went out 21 business days after receiving the order, with the remainder sent five business days later.

“The contractor was extremely pleased with the formliners in regard to ease of use and timeliness of delivery, allowing the contractor to maintain the project schedule,” said Gilbert.

Western Pacific Precast manufactured the panels at its plant in Sloan, Nevada. Every formliner size was mapped out digitally to ensure proper orientation. All of the concrete had to achieve proper strengths and the design pattern had to achieve the proper setup from the molds for acceptable levels of quality. The structural system required that these panels tie into each other to create the outer exterior.

To support the precast panels, the firm delivered a steel frame structure that carries gravity loads with the panels attached to the steel frame. Inserts in the panels and rods in the inserts tied the concrete together.

“A fair amount of coordination was required between the design team and the steel and precast fabricators to maintain tolerances,” Schiller said.

Green Elements Inside and Out

Designed to receive LEED Silver Certification, the project is highly energy efficient.

“Sustainable features such as building orientation, recyclable materials, energy efficiency above code standards and drought-tolerant landscaping play an important role in the project,” said Burns.

Coda Group, Inc., a Nevada-based architecture and sustainability consulting firm, worked with the design team to achieve LEED Silver status. The company’s Jennifer Turchin helped facilitate decisions such as specially designated parking spaces for low-emitting and fuel-efficient vehicles, plumbing fixtures designed to conserve water, and material selection that focused on regional and recycled content. The project also achieved sustainable sites category points for its location in a primarily suburban area that has many urban amenities, including access to public transportation and development density.

Coda also assisted with construction policies addressing waste management and indoor air quality.

As part of the effort to receive LEED Silver certification, the project team also sought Materials & Resources Credit 2: Construction Waste Management. To achieve this credit, Coda worked with VCC, the general contractor, on recycling and/or salvaging nonhazardous construction and demolition debris and implementing a construction waste management plan that at a minimum identified the materials to be diverted from disposal and whether they would be sorted on-site or commingled. Calculations were done by weight or volume, and they had to be consistent throughout the project.

The selected waste management provider was required to provide documentation to VCC on a monthly basis. This included a summary log of all construction waste generated by type, the quantities of each type that were diverted and sent to a landfill, and the total percentage of waste diverted from landfill disposal. The waste-management provider was also required to provide waste-hauling tickets for each load removed from the project site.

Coda Group also assisted VCC in creating an indoor air quality management plan. Construction was sequenced in such a way that porous building materials were protected from exposure to moisture and stored in a clean area prior to installation. This was accomplished by the use of temporary enclosures to protect the material from moisture, the timing of applying fireproofing to prevent unnecessary moisture exposure, and the use of a temporary vapor barrier such as single-ply roofing, which could later be incorporated into a final roof system. In addition, the general contractor ensured other areas maintained compliance including HVAC protection, source control of emitting products and equipment, pathway interruption and housekeeping.

“Even with a complex building program and desire to achieve LEED Silver Certification, this team was able to meet the client goals and deliver a successful project,” said Kent Bell, president of Harris Consulting Engineers, the mechanical, electrical and plumbing consultants who performed the energy modeling.

NAIOP’s Southern Nevada Chapter recently recognized the project with the 2019 Spotlight Honor Award in the Spec Office Building category.

Lori M. Lea is the owner of AECIndustryPro.com LLC