Standardization and Panelization in Multifamily Housing

These high-tech construction techniques can save time and money on projects.

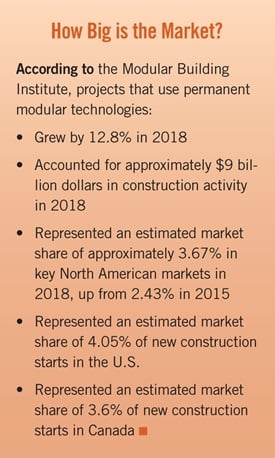

For many years, modular construction was dogged by concerns about quality and cost that prevented it from achieving wide market success. That’s changing now, thanks to advances in supply chains, building information modeling (BIM) and construction management. In contrast to earlier modular construction, today’s prefabricated solutions have the potential to deliver quality construction at lower cost, particularly when it comes to labor.

For example, construction startup Katerra, which specializes in modular construction, built a 24-unit garden-style apartment in Las Vegas in 90 days in 2019. That’s about 50 days faster than typical stick-built units.

“Framing time took less than half the time as status quo for typically stick built construction,” according to a white paper published by Katerra after the project, dubbed K90, was finished. “Installation of the mechanical, electrical, plumbing and fire-protection engineering systems took less than half the time of traditional construction — and much of the labor was in factory production, instead of the field. The drywall team was able to complete installation in three days per floor, when traditionally it takes more than five days per floor.”

Modular construction can be a good choice for workforce housing and other mid-market housing developments where affordability is a primary consideration. Investment groups focused on high-rent/high-density projects are now exploring projects with lower rent rates, especially in semi-suburban markets.

There is a genuine need for this type of housing. According to the Harvard Joint Center for Housing’s “State of the Nation’s Housing 2019” report, 47.4% of renter households in the U.S. are considered cost-burdened. That means they spend more than 30% of their income to pay for housing. Among that group of renters, 10.8 million are considered severely cost-burdened, spending more than half of their incomes on housing.

Because builders have been focusing on higher-end units in recent years, the amount of lower-rent stock has decreased. A 2017 report by the National Apartment Association and the National Multifamily Housing Council predicts that the U.S. will need to build more than 4.6 million new rental units to serve all income levels by 2030. To achieve that, builders must construct more than 325,000 units a year, an increase from the average of 244,000 units that were built between 2012 and 2016.

An Overview

A 2020 report from Fannie Mae, “Multifamily Modular Construction Toolkit,” provides an overview of modular construction.

According to the report, modular construction is a technique in which most of the construction of a building is done off-site, often in a specialized factory. The components, called modules or boxes, are then transported to a jobsite for assembly. This technique is used to build multifamily housing, as well as hospitality and health care facilities.

There are two broad categories of modular construction. In panelized construction, two-dimensional building elements such as walls and frames are built in a factory, then transported to a jobsite for assembly. Volumetric construction involves the off-site prefabrication of three-dimensional, enclosed units that are then transported to the jobsite and assembled to form a building.

Evolving technology has made prefabricated solutions relevant. This includes BIM modeling, which allows stakeholders to see in 3-D what a completed space will look like. As a result, designers can get buy-in at the earliest stages of design before components are manufactured in a factory. This paves the way for pre-engineered solutions that can be designed to meet the specifications with precision and cost savings.

This process of pushing decisions to earlier in a project also facilitates vertical integration — supply chain, construction and manufacturing working together as a single entity.

BIM’s precision is increasingly important because it directly informs the manufacturing process.

Precision results in less construction waste on the site and in the cost of materials. It is more efficient to process the materials at the factory than at the jobsite, and the environmental footprint is reduced as well.

The virtual model impacts the final product, too. Sizing parameters that can be reduced in a standardized building would be impossible in a conventional building. For example, tolerances within one inch are considered adequate for conventional construction, whereas tolerances can scrutinize down to almost zero in manufactured panels. When taken in the aggregate throughout the whole unit, the inches gained through these tighter tolerances begin to translate into livable space in the unit.

In addition to increasing rentable space, higher precision also saves money. For example, when the depth of the wood floor trusses on one building was reduced from the standard 18 inches down to 16 inches through early detail work, the height of the entire building went down. Multiplied by all 12 three-story buildings in the project, this seemingly minor two-inch change saved tens of thousands of dollars in exterior skin materials cost.

Finally, panelization assemblies typically require far fewer workers than would be needed for ground-up construction. This can produce big savings in labor costs, a key consideration during a time when there are worker shortages in the construction field.

According to a 2017 report from the Terner Center for Housing Innovation at the University of California, Berkeley, current modular construction techniques can save up to 20% on the cost of building a three- to four-story wood frame multifamily apartment building. These savings come from reducing labor time and costs, economies of scale in material use and procurement savings.

Challenges and Solutions

Every detail must be resolved and understood before the first panel is manufactured. To begin with, panel dimensions affect both how they’re sized to ship and how they’ll be connected — panel to panel, panel to floor and ceiling, etc.

Then, details such as the openings for water lines and electric wires are determined. Because those will be cut into the panels before they ship, precision is essential. Much of this work can be done by robots in a factory.

Details affect logistics, too. Panels must be properly sequenced — completed and then transferred to trucks in the correct order. That order will determine the sequence of installation.

One of the key strategies for standardizing design is reaching agreement on important decisions early on. Depending on the process, manufacturers can develop libraries of predesigned floorplans and units based on detailed feedback from developers. Facilitating this early buy-in places the developer in the role of a design partner who can reinforce the concept of standardization and resist requests to make changes later in the project.

Another challenge is arranging the sections on the building’s exterior to create visual interest and variety. The goal is a building that doesn’t look like a prefabricated product.

The common perception of modular construction is of finished units that resemble stackable boxes. However, today’s standard panelization approach incorporates ready-to-assemble components — walls, floors, bathrooms, utility rooms, kitchens — that are manufactured in a factory, shipped to a jobsite and then assembled. This allows teams to incorporate prefabricated components without the look of stacked boxes.

Developers can arrange the components as they see fit as long as they stay within the design parameters to realize the benefits of the modular approach. For example, a decision during the design process to maintain a 12-foot width limit for an apartment unit must be adhered to in order to accommodate the transportation of panels or modules to the jobsite.

Innovation in Practice

Optimizing the size of shipping pieces is part of managing the supply chain, where involving logistics early in the process is a key part of the vertical integration. For example, designers need to factor the width of a truck driving down the road into the dimensions of panels and modules. Whether a panel is 12 or 8 feet wide can have major implications for the entire process.

Another example includes standardizing exterior wall panels with pre-installed windows. One breakthrough suggestion that is being used today is an 8-foot-by-8-foot panel with door and window configuration holes. A series of these panels, comprising fewer than a dozen different window/door configurations, could result in fewer panels manufactured overall while still providing variations in elevation. That would help the building look and feel more interesting and dynamic, while standardizing the bulk of the wall.

Yet another example is an innovative second wall at the back of a kitchen, a layer that helps standardize the kitchen module so plumbing can be installed in the factory. As a bonus, the second wall creates a space not just to house plumbing, but also to recess the refrigerator, making it appear more like a high-end built-in appliance.

The technical advances in the industry that have led to these increased efficiencies also result in higher-quality living spaces. This is an intended but perhaps surprising benefit that unquestionably adds value to a development. That value is reflected in rent rates, market share, leasing velocity and tenant retention.

Hill Pierce is an architect with Katerra. Carl Malcolm, AIA, is the vice president of JHP Architecture / Urban Design.